EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

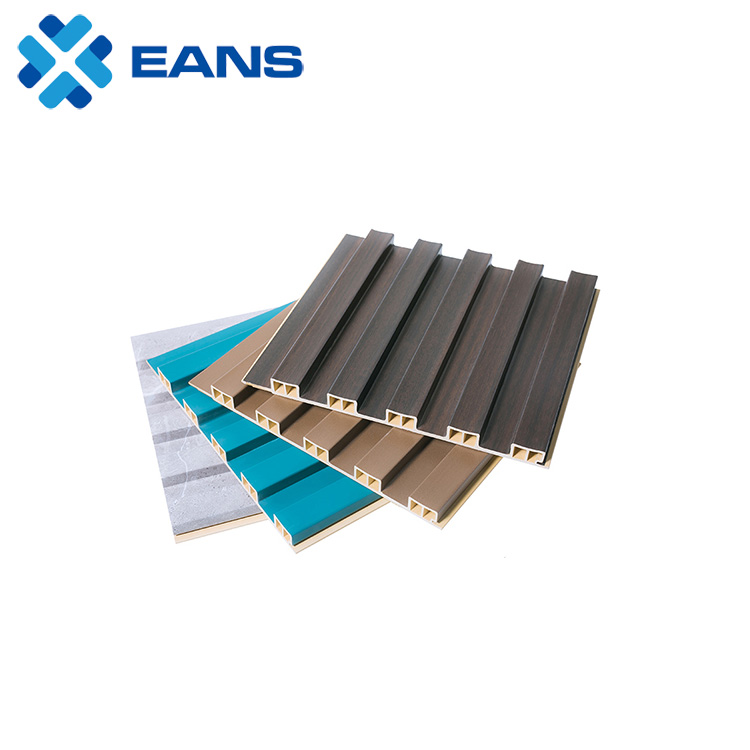

Eans Machinery offer China best Top Quality WPC Fluted Wall Panel Making Manufacturing Process Machine, WPC profile making machine

Inverter: |

|

Schneider: |

|

Motor: |

|

Temperature contoller: |

|

Place of origin: |

|

Eletric: |

|

Temperature controller: |

|

Steel: |

|

Speed: |

|

Screw and barrel: |

|

Guarantee time: |

|

Votage: |

|

2. Changing the moulds to produce many kinds of different PVC profiles.

3. Auxiliary machine: Mixing unit, crusher, pulverizer, laminating machine...

Parameters of Charcoal PVC WPC fluted wall panel machine :

| Model | SJ 65 |

| Diameter of screw | 65/132 |

| Speed ( KG /H) | 260 |

| Weight ( KG ) | 4000 |

FAQ:

We will arrange our engineer to the customer factory for installation and teach local workers to operation and maintenance. We also can send the experienced master to work at customer's factory three months or more according to requirements.