EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

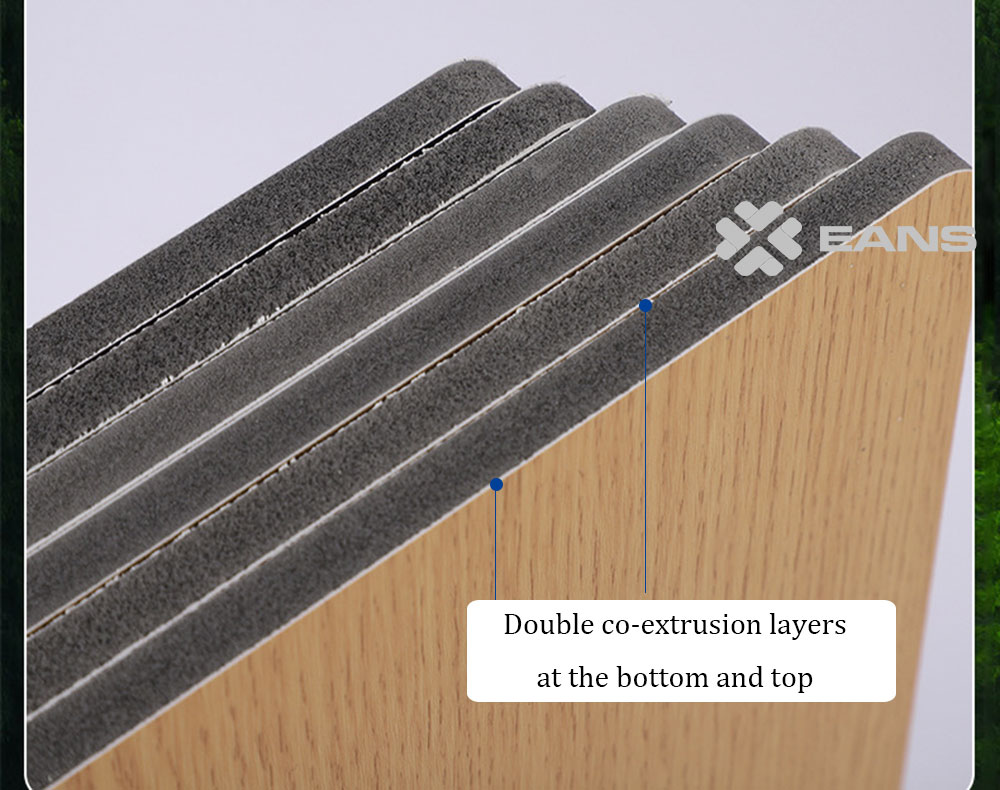

The co-extrusion foam board has double-sided co-extruded layers, which are stronger than ordinary foam boards. The co-extruded PVC WPC foam board is stronger for cabinet boards, billboards, bedroom boards, and so on.

Inverter: |

|

Schneider: |

|

Motor: |

|

Temperature contoller: |

|

Place of origin: |

|

Screw and barrel: |

|

Warranty: |

|

PLC control: |

|

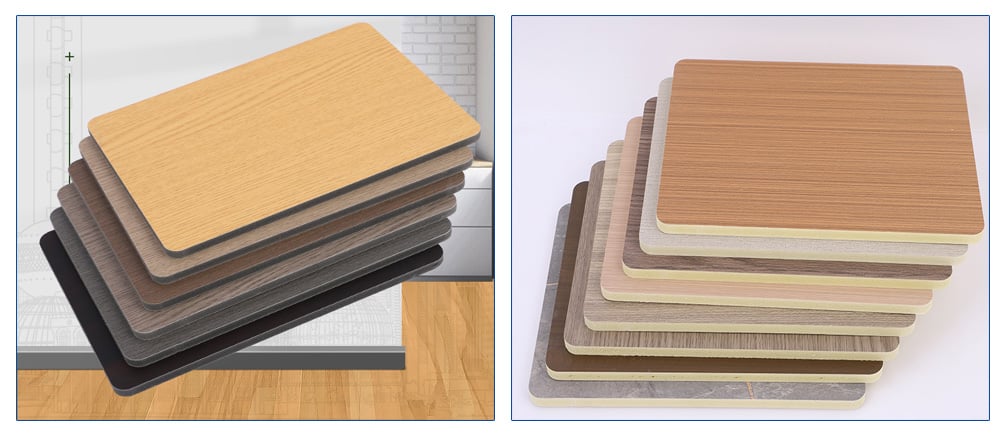

PVC WPC foam board has such characteristics as sound separation, sound absorption, heat separation, temperature-keeping, etc.

The material is incombustible, it is safe for use.

The surface of this product is smooth, it can be printed. (Clean the surface before printing.)

WPC PVC Foam Board Application:

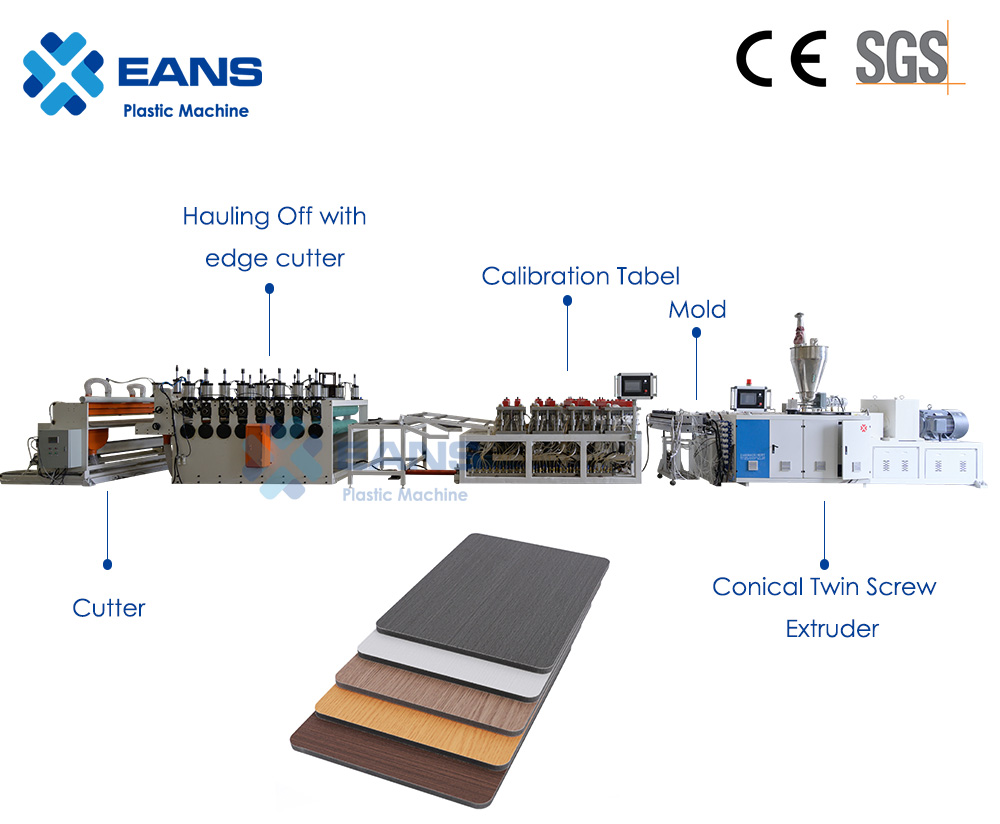

Parameters of WPC PVC Foam Board Production Line

| Model | SJ80/156 | SJ92/188 |

| Board Width | 915/1220 mm | 1560/1830 mm |

| Board thickness | 3-25 mm | 3-25 mm |

| Capacity | 400 kg/h | 550 kg/h |

| Main motor power | 75 kw | 132 kw |

Features of WPC PVC foam board production line

-The conical twin-screw extruder has stable performance, which can make the melt plasticize well at a lower temperature. The cast aluminum heater is installed on the cylinder, which has high thermal efficiency, fast and uniform temperature rise, and is equipped with a cooling fan.

- Fetching in Europe and America advanced technology and uniting with domestic conditions, our company develop this WPC PVC foam board production line. The production line adopts plastic processing techniques such as extrusion, molding, and injection molding to produce plates or profiles.

Die Head (Special mold that can make WPC and PVC foam board)

Function: extrusion and molding of the PVC WPC foam board, Using high-quality and durable raw materials.

Advantage: Die head with streamlined runner surface, two half mold body design, die head disassembly, easy to clean.

Product size: 1220 mm * 2440 mm (3 mm, 5 mm, 6 mm, 8 mm, 10 mm, 12 mm, 14 mm, 16 mm, 18 mm, 20 mm, 25 mm, 30 mm, 35 mm, 40 mm, etc.), the length and thickness are adjustable.

Calibration Mold

Four pairs of calibration foaming molds, All the surface of the runner is plated with hard chromium, the average thickness is 25μm~50μm, and mirror polished.

The cooling type: water cooling

The WPC PVC foam board production line video: