EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

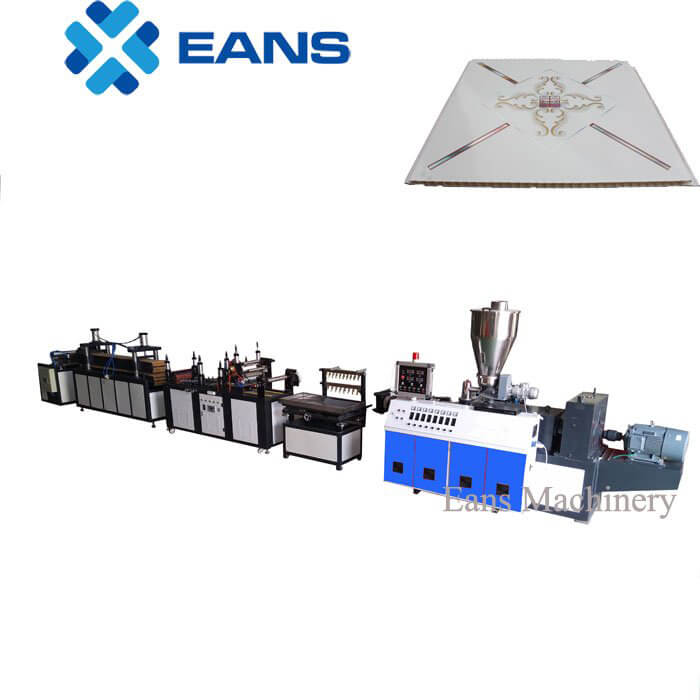

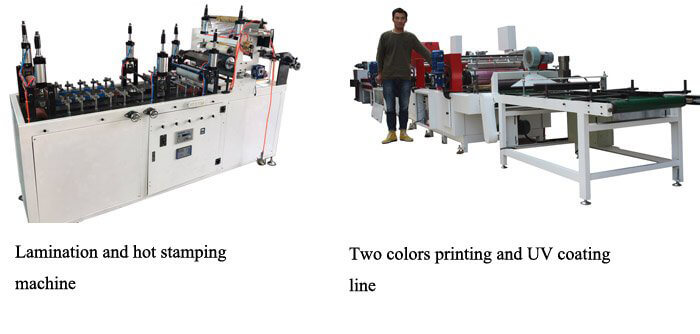

PVC ceiling production line is used to make PVC ceiling panel with different width,such as 200mm,250mm,300mm and 600*600mm.The popular surface treating of PVC ceiling is hot stamping or printing.

Inverter: |

|

Motor: |

|

Eletric: |

|

Temperature controller: |

|

Steel: |

|

Speed: |

|

| Model | SJSZ48/113 | SZSZ55/110 | SZSZ65/132 |

| Applicable width | 150 to 200mm | 250-300mm | 400-600mm |

| Extruder | SJSZ48/113 | SJSZ55/110 | SJSZ65/132 |

| Capacity(kg/24hours) | 2200 | 3000-3500 | 4000-5000 |

| | >800m2/24hours | >1200m2/24hours | >1600m2/24hours |