EANS PLAST - PROFESSIONAL PVC SHEET BOARD EXTRUDER

Hot line: +86-18963696671

WPC boards are composited boards from a mixture of PVC resin, calcium carbonate, and plastic additives. Now, it has become an ideal building material for residential and commercial use. Combining the advantages of different materials, WPC louvers are stronger and more durable than solid wood, but their appearance is also similar to solid wood. Unique mixed-color technology makes the WPC louvers look closer to natural solid wood.

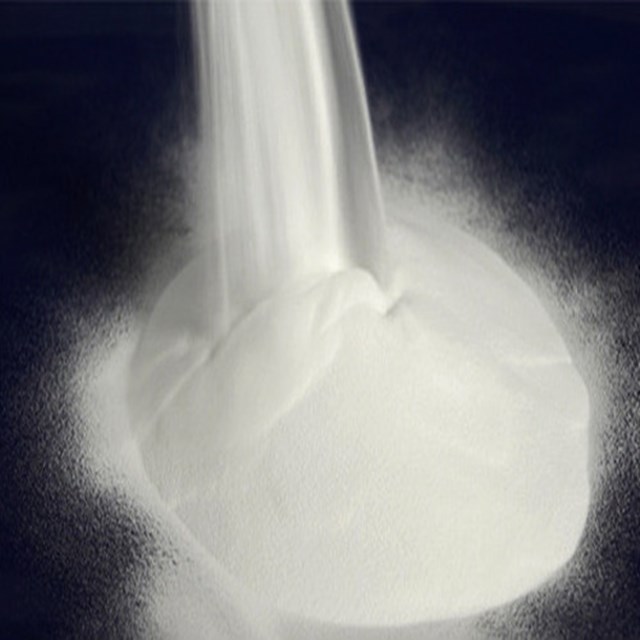

Calcium Carbonate

PVC Resin Powder

Stabilizer (Ca/Zn)

Foaming Agent

Steacid Acid

PE wax / Carbon black

ACR / CPE

Pulverized materials

NOTICE: Based on the above formula each manufacturer is slightly different.

PVC Resin: PVC is a non-toxic, odorless white powder. It has high chemical stability and good plasticity. PVC is the most widely used and most important polymer in the world, but pure PVC is actually the most unstable polymer, so only after adding appropriate stabilizers and other additives, the advantages of PVC can be realized.

Carbon Black: the pigment with the strongest tinting power and hiding power, the most stable pigment, heat resistance, chemical resistance, and light resistance

Calcium Carbonate: insoluble in water and soluble in acid, function: increase opacity and improve flexibility.

CPE: As an excellent impact modifier with high-cost performance, it can promote PVC plasticization, improve processing performance, and can greatly improve the impact strength of products, and significantly improve its low-temperature resistance and weather resistance.

Stabilizer: It can slow down the reaction, maintain chemical balance, reduce surface tension, prevent light, thermal decomposition, or oxidation reactions, etc., thereby promoting product quality stability.

Materials Heating and Cooling Mixer

WPC/PVC Louvers Extrusion Machine

Offline WPC Louvers Wrapping Lamination Machine

Waste WPC Crusher

WPC Pulverizer

WPC Louvers Manufacturing Process

1. Mixing Materials

First, Put the PVC resin powder, foam agent, stabilizer, and calcium carbonate into the screw feeder according to the formula ratio, Secondly, the feeder puts the materials into the heating mixer, thirdly, the materials be transferred into the cooling mixer. The mixing time is around 8-12 minutes per batch.

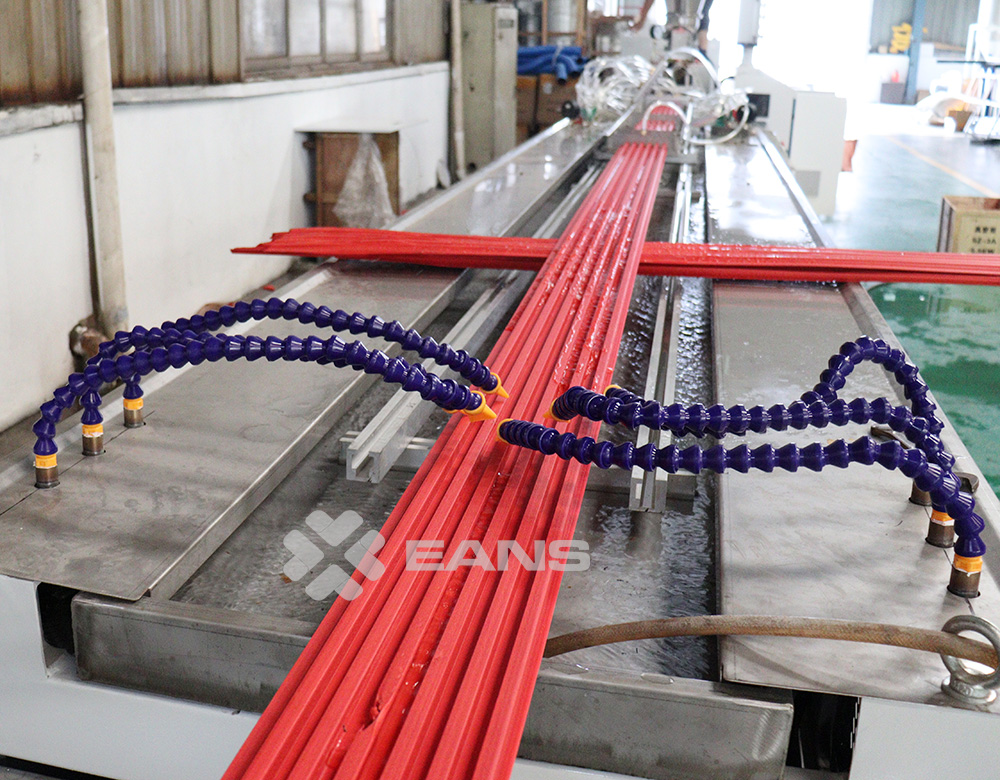

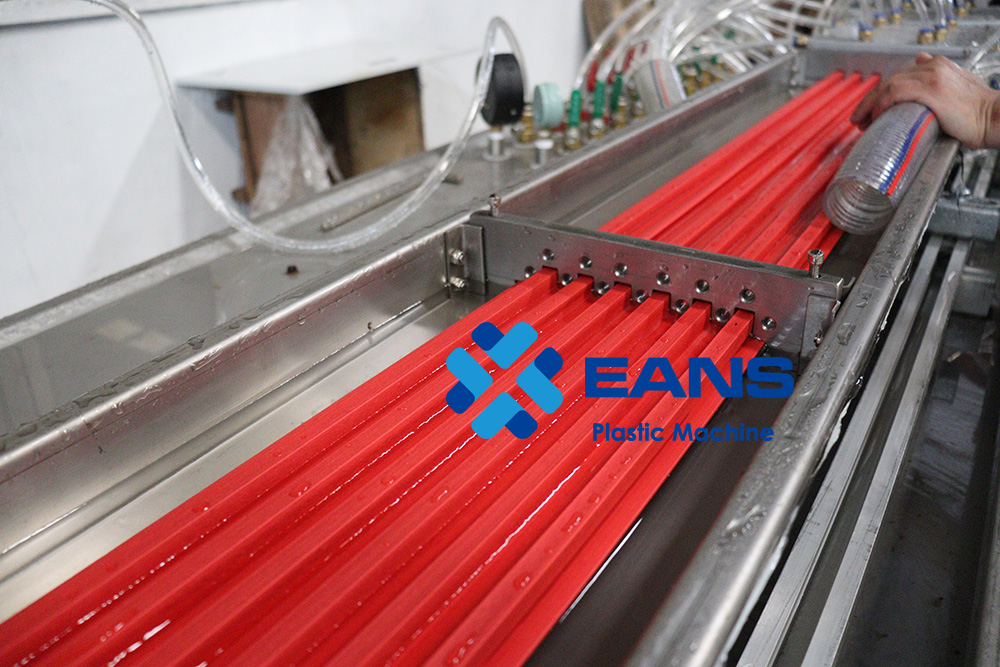

2. WPC/PVC Louvers Extrusion Machine

The mixed materials be poured into the screw feeder in the extrusion machine, and extruded through four heating zones. The WPC louvers extrusion machine adopts a conical twin screw and barrel which can make the WPC louvers with low cost and stable performance. By changing the extrusion die and calibration mold, the WPC louvers machine can make panel width150 mm, 160 mm, 170 mm, and so on.

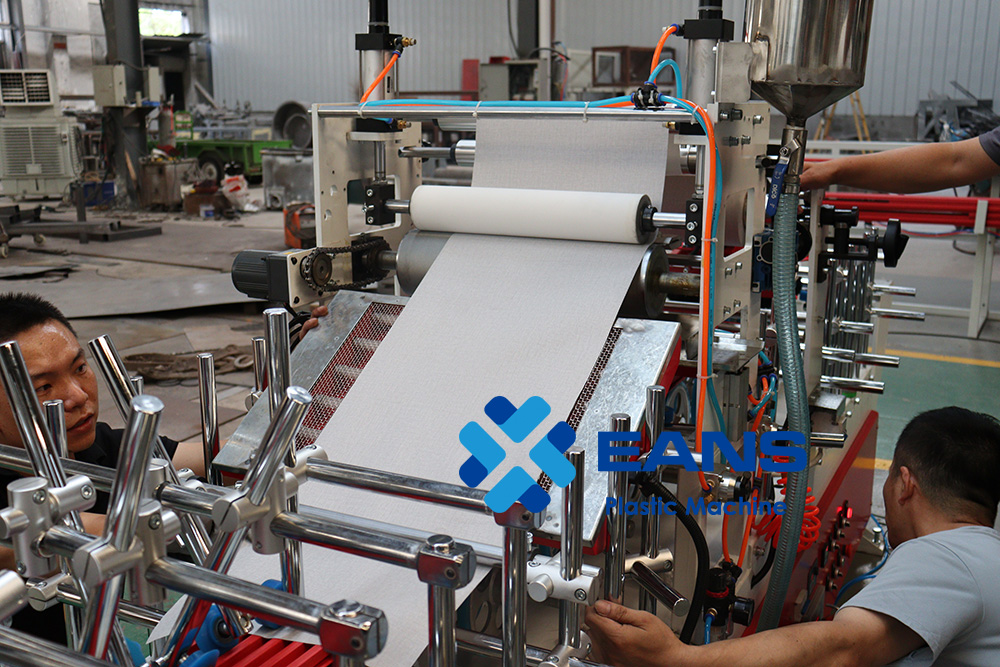

3. WPC Louvers Lamination Machine

Put the extruded WPC louvers into the conveyor belt, apply a layer of PVC film uniformly by the roller, and then enter the oven for baking. The WPC lamination machine is equipped with a dust-free cleaner, a pre-heating device, an unwinding device, and a transmission device.

Equipped with multiple sets of wheels to make each groove evenly covered

WPC louvers are a popular and durable option for homeowners and businesses alike. Knowing how WPC louvers are made can help you make an informed decision when choosing the right flooring for your needs. With its many benefits and manufacturing process, WPC louvers are a great choice for those looking for a high-quality, affordable flooring option.

Eans Machinery is a WPC louvers production line manufacturer from China. We gain an SGS CE certificate for exportation to European countries. Our machines are sold to more than 30 countries across America, Brazil, Serbia, the middle east, Africa, and Asian countries. After years of technology accumulation and product innovation, our company has won a good reputation in the market. "Business integrity, quality first" is our principle. Our company is equipped with a professional team of quality control and after-sales service staff members to keep track of each order scientifically so as to provide high-speed services for customers. We insist on the tenet of "professional development, improving our skills". We help to set up your factory as our own home with our pure heart, Your satisfaction is our goal, welcome your negotiation and cooperation!